LKM cable trunking: Reliable protection for cables

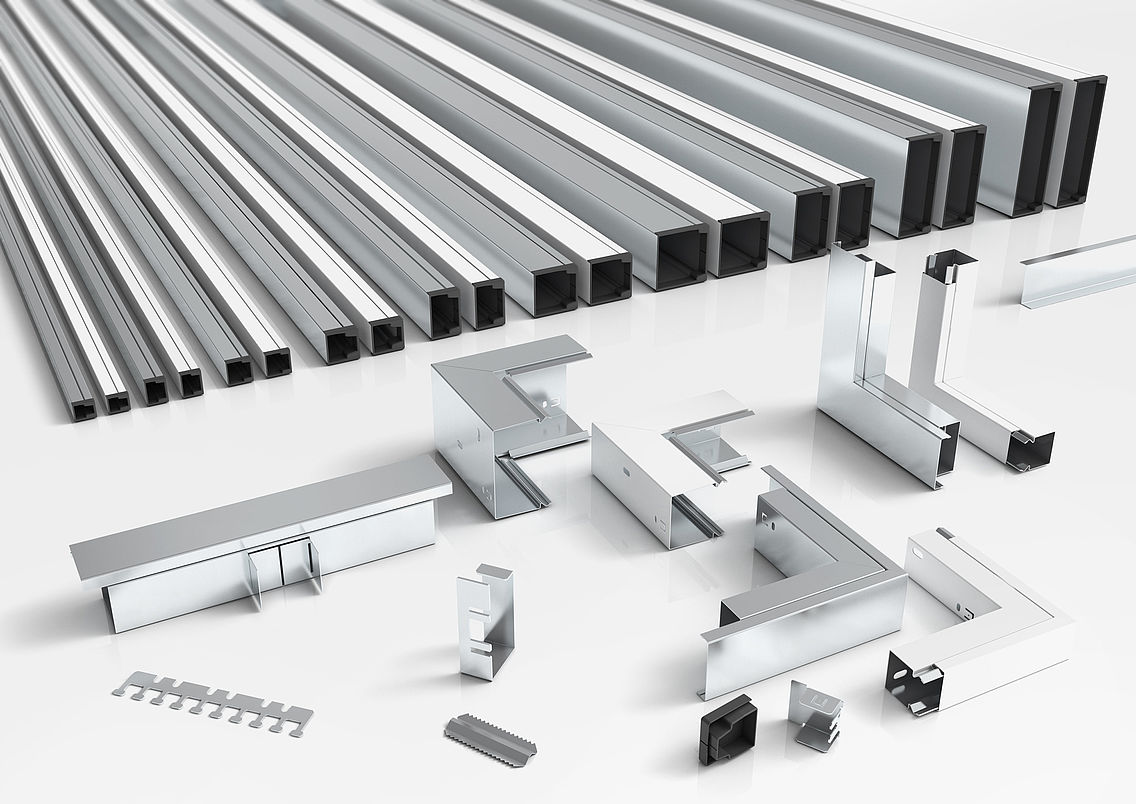

The metallic OBO LKM cable trunking has regularly proved its worth as a stable system in a rough environment, such as an industrial environment or plant construction. It forms a complete system, which allows simple installation at a later date, also with pre-terminated connectors. The trunking system reliably protects cables of machines and systems against mechanical loads and soiling. As a result, cables are routed not just safely but also in an attractive manner. The trunking is supplemented with fittings and accessory components, such as edge protection rings and end pieces, which make the system even more flexible.

Edge protection rings: Time-saving, uncomplicated retroinstallations

The edge protection rings of the LKM system can be retroinstalled in an uncomplicated manner – even if the trunking is already mounted on the wall or even if it is already equipped with cables. The attractive appearance and the user-friendly handling are the hallmarks of the edge protection rings, which are made from halogen-free material. Closed end pieces are available in the same design.

Cable trunking for any challenge: Selection of sizes and surfaces

A total of ten different trunking sizes are available in the LKM system, making it quick and easy to find the right LKM trunking for any installation project. All the trunking is available with the surfaces FS (strip galvanised) and FSK (strip galvanised and with a pure white plastic coating). Special solutions in all RAL shades are available. This means that the LKM trunking fit in visually in different installation environments. The OBO selection aid offers an overview of all the cable trunking and can guide you to the right LKM variant in just a few steps.

Protection and the maintenance of electrical function

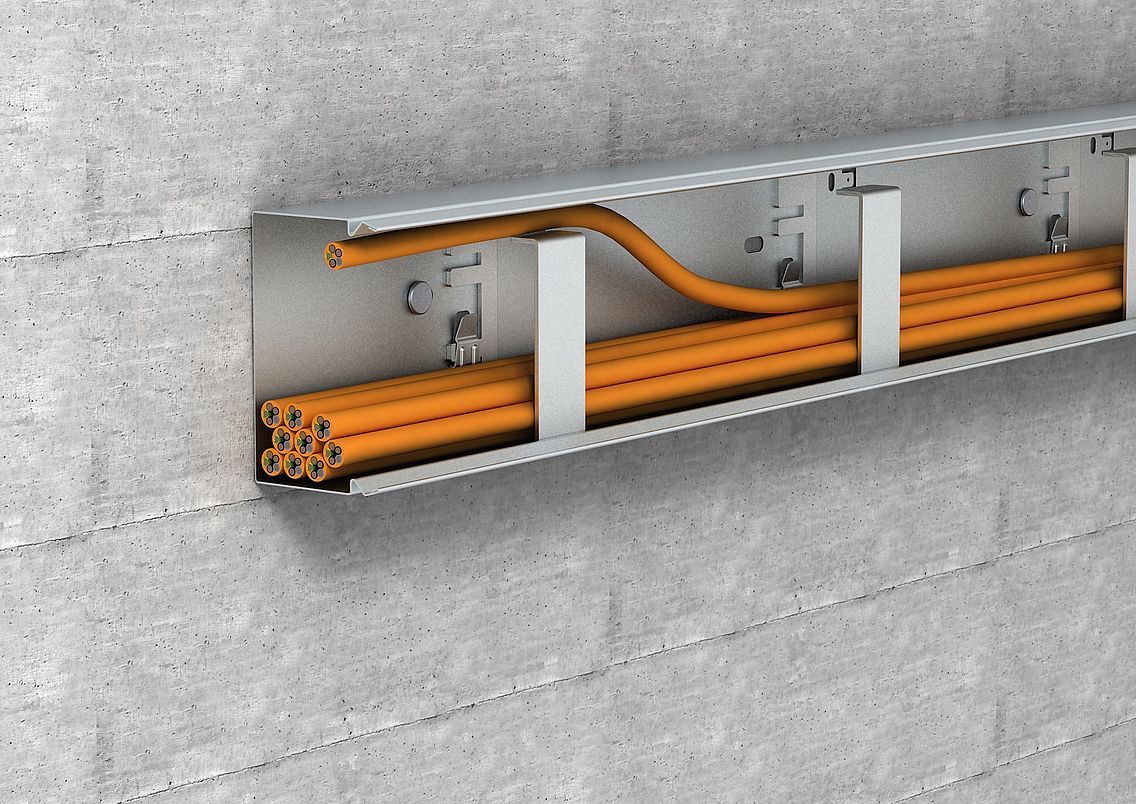

The LKM cable trunking can prove itself in the routing and protection of cables and with regards to the maintenance of electrical function. Cable routing with metallic LKM cable trunking is approved as a cable-specific routing type according to DIN 4102 Part 12 for the maintenance of electrical function classes E30 to E90. The LKM20030 trunking has been specially tested for fire and telecommunications cables. The LKM60100 trunking has been tested for power, fire and telecommunications cables.

Practical installation

The LKM cable trunking is also suitable for horizontal wall and ceiling mounting. With type LKM60100 trunking, a retaining clamp can prevent the cables from falling out. Once the cable installation has been completed, the trunking cover is locked onto the trunking base with ultimate ease. The equipotential bonding between the cover and base and between the trunking lengths is guaranteed without the use of additional connection cables. This saves time and offers reliable protection.

Thought-out down to the last detail

Many ingenious mounting details make the LKM cable trunkingextremely reliable companions during cable routing:

- The edge protection ring is placed on the open ends of the LKM trunking, preventing damage to the cables within.

- The edge protection rings offer additional flexibility, as they can be retroinstalled in an uncomplicated manner – even if the trunking is already mounted and is even already equipped with cables.

- The partition is inserted into the straps located on the base, guaranteeing equipotential bonding without any additional aids.

- After installing the LKM trunking, the joint connector is locked into the parts to be connected from inside, guaranteeing equipotential bonding between these two parts.

- The special cover contour guarantees safe equipotential bonding between the cover and the base.

- The trunking is earthed using the connection strap located on the base.

- The cable bracket is mounted using the trunking fastening screws. The cables can be held using type 565 cable ties.